Cold Rolled Steel

Cold Rolled Steel

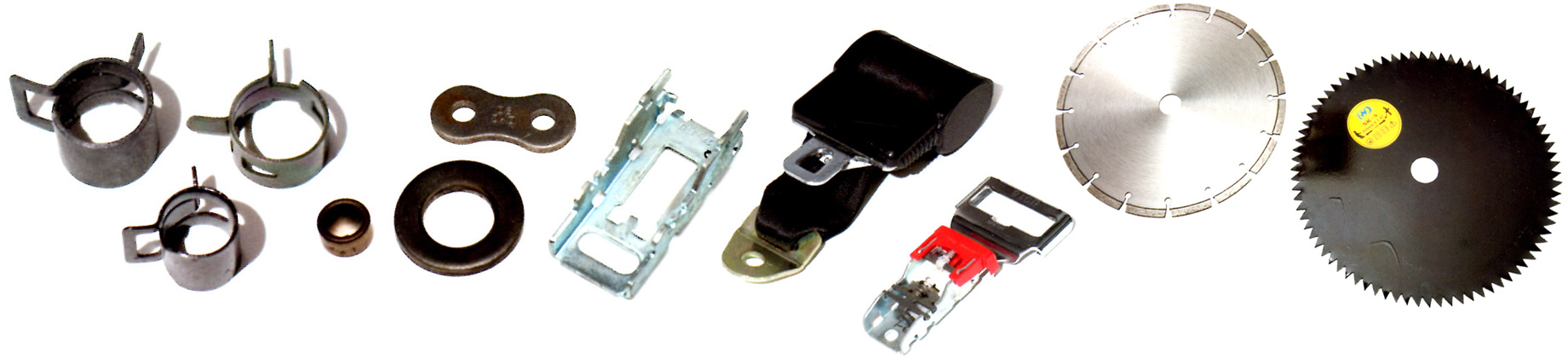

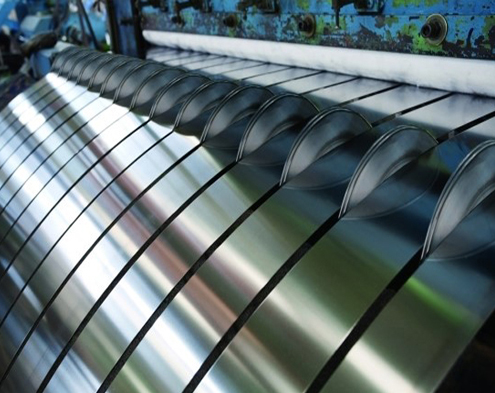

Cold Rolled Steel Strips are classified as general and special steels, General steel is the most basic cold-rolled product and is widely used in automobiles, home appliances, construction materials, and various industrial devices.

Special steels have different chemical and mechanical properties depending on their application, and are often used when specific properties such as stability, precision, wear resistance, and anxiety are required depending on the application.

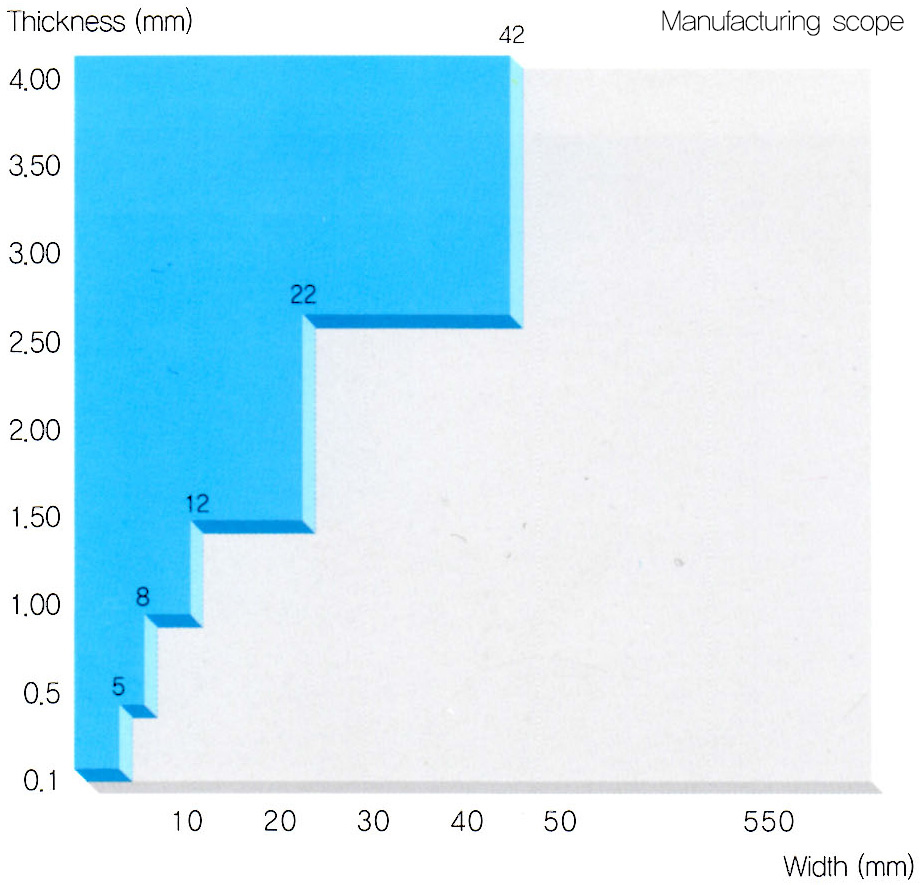

Referred to in the context of cold-rolled steel, general steel means steel containing 0.15% carbon or less. It's major final use is for press forming (drawing, forming, bending) and so heavily requires maximum processing, refined thickness and stable formation, and for post-processing, surface treatment such as plating and painting to create the appearance desired. At present, we are fully equipped with all necessary facilities for cold rolling and we are responding to the customer's needs.

Cold rolled steel has a wide range of uses, the most common being in steel products like automobiles, appliances, construction materials, and all types of industrial equipment. Used to produce a large array of materials, it boasts superior processing and precision capability and a superior surface which places it in high demand for the manufacture of automotive parts.

| Item | Application |

|---|---|

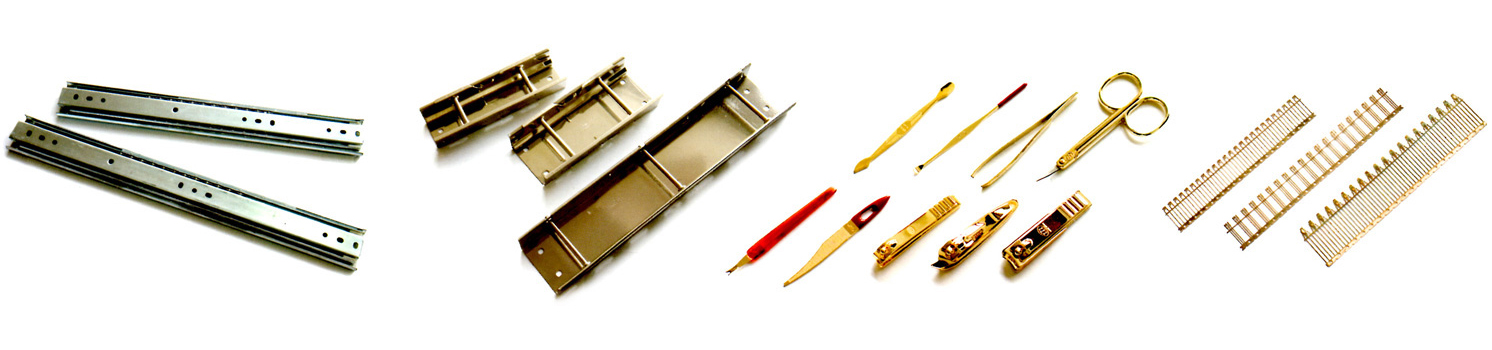

| Automobile-related products | Products for interior/exterior (Seat belts), engine parts, transmissions, etc. |

| Appliance-related products | nail cutters, refrigerators, washing machine exteriors, electronic components, etc. |

| Other | All types of steel appliances (washer clips, etc.) |

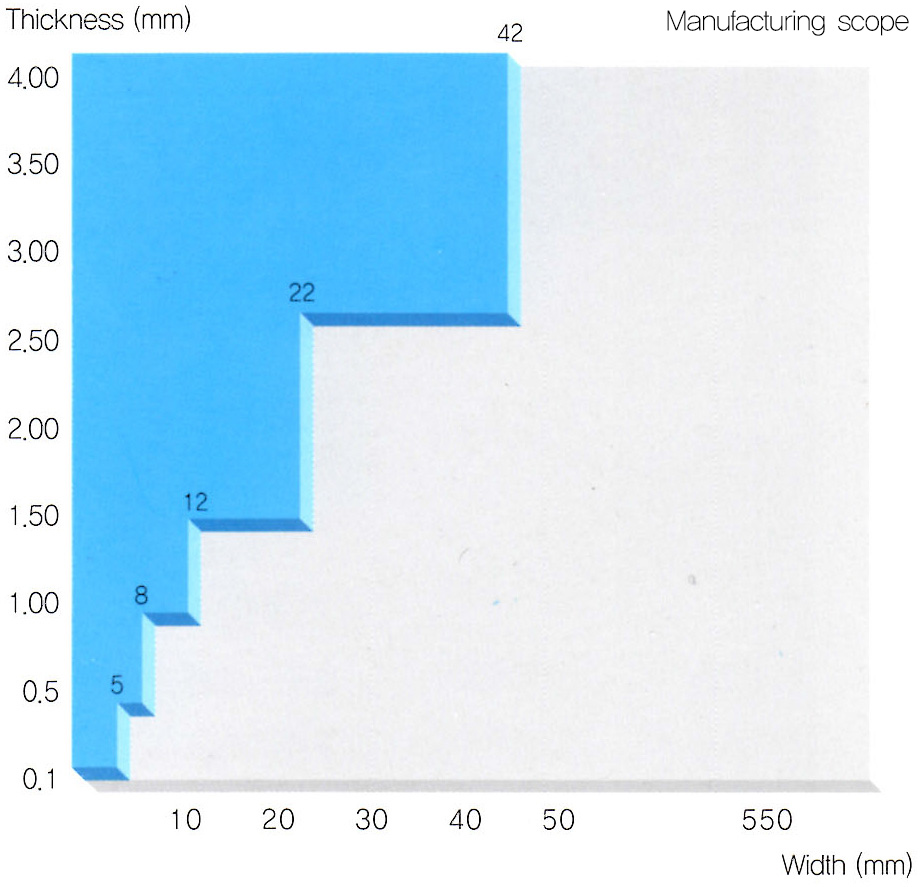

Special steel refers to high carbon steel and special alloy (Mo, Cr, V, Ni, Badded) with a carbon content of 0.30-1.20%. Heat treatments like carburizing, immersion, quenching and tempering are applied for use in equipment parts with repetitive, high-wear requirements. Characteristics of special steel Special steel refers to high carbon steel and special alloy (Mo, Cr, V, Ni, Badded) with a carbon content of 0.30-1.20%. Heat treatments like carburizing, immersion, quenching and tempering are applied for use in equipment parts with repetitive, high-wear requirements. Its manufacturing characteristics involve management of ingredients and of non-metallic inclusion, and the spheroidizing of carbides during processing to guarantee user workability and heat treatability. It is also important in technology for gage control indispensible for equipment parts, and it is thus managed more strictly than general steel and requires rigid systematization. Our company is equipped with a thickness automatic control system and has innovated the process from 20 high Cold Mill.

Cold rolled steel has a wide range of uses, the most common being in steel products like automobiles, appliances, construction materials, and all types of industrial equipment. Used to produce a large array of materials, it boasts superior processing and precision capability and a superior surface which places it in high demand for the manufacture of automotive parts.

| Item | Application |

|---|---|

| Automobile-related products | Seat belts, seat recliners, transmissions, door latches, seat rendiner, and all interior/exterior components. |

| Other | All types of industrial saw, springs, safety hats, needles for use in textile manufacturing, etc. |

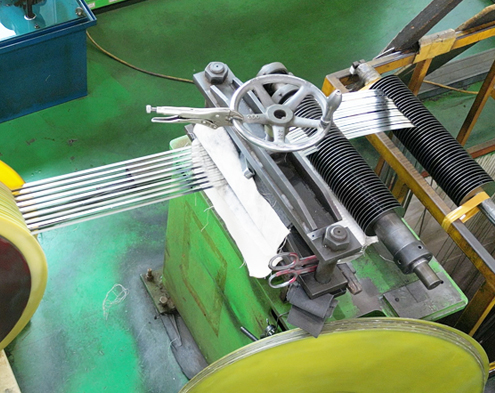

Slitting

Slitting

PO, CR, seat belt spring, etc. are cut and supplied in width and weight according to the customer's request.

| Sortation | Specification |

|---|---|

| Width | 600mm ~ 1,400mm |

| Thickness | 1.2mm ~ 10.0mm |

| Sortation | Specification |

|---|---|

| Width | 9mm ~ 650mm |

| Thickness | 0.1mm ~ 8.0mm |

| Sortation | Specification |

|---|---|

| Spring Width | 4mm ~ 300mm |

| Spring Thickness | 0.0mm ~ 2.5mm |

| Material | SAE1078(Posco POSA1081) |

| Durability Rotation Test | Over 150,000 Times |

| Hardness | Customizable |

| Coil Inner Diameter | 300mm standard |

| Coil Outer Diameter | 750mm-900mm standard |

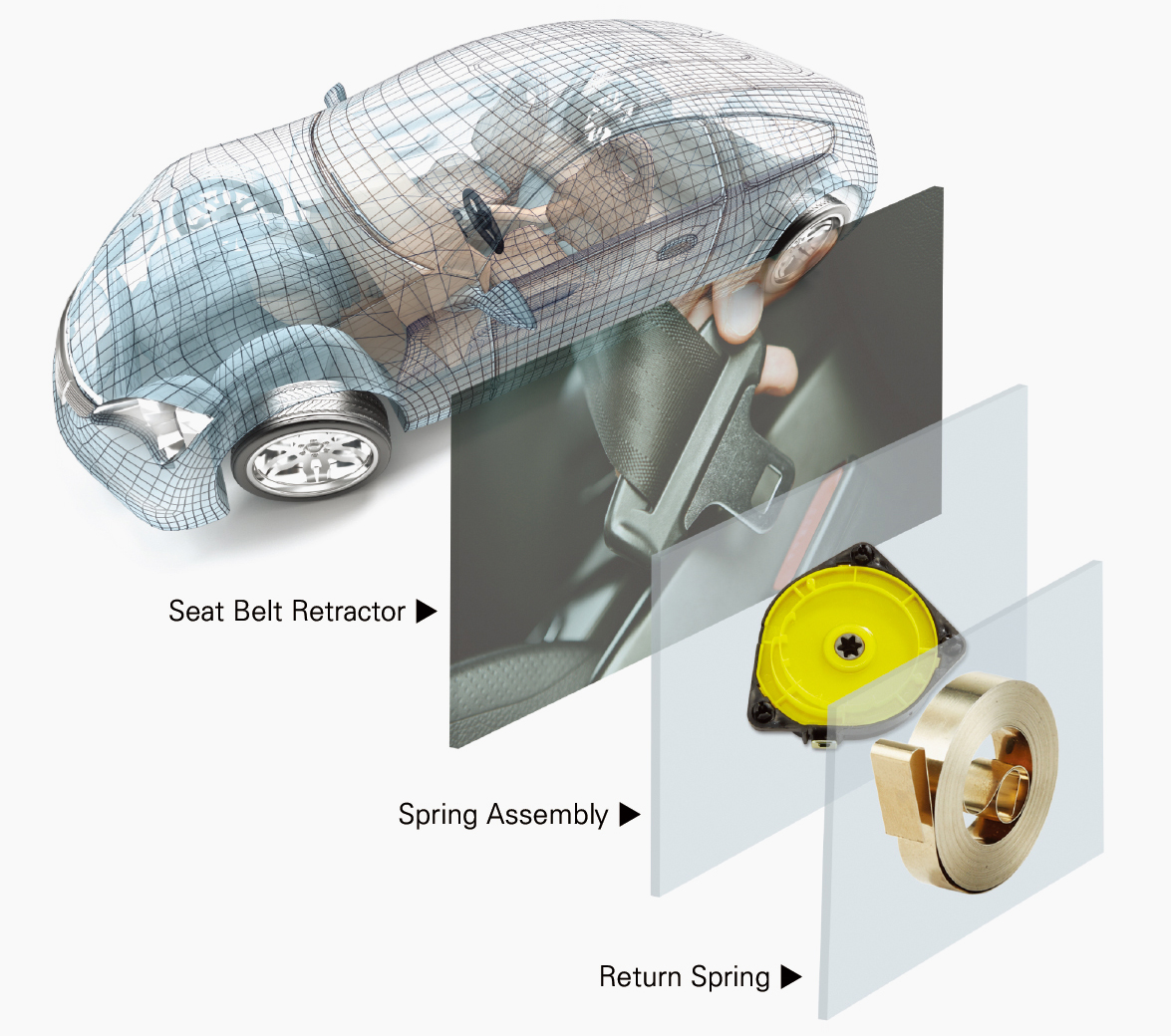

Seatbelt Spring Assembly

Seatbelt Spring Assembly

| Sortation | Specification |

|---|---|

| Spring Width | 4mm ~ 300mm |

| Spring Thickness | 0.0mm ~ 2.5mm |

| Material | SAE1078(Posco POSA1081) |

| Durability Rotation Test | Over 150,000 Times |

| Hardness | Customizable |